Estimated studying time: 6 minutes

It’s not each day I get to tour a thermal producer’s facility. So when Pulsar invited me to take a look at their Lithuanian headquarters, which additionally serves as certainly one of their major meeting areas, I couldn’t move it up. Over every week, our group obtained to see how thermal optics are assembled, examined, and ready for cargo. We additionally had the chance to check out your entire product line and supply direct suggestions to the workforce. Right here’s a better take a look at what I realized.

Pulsar ProStaff

I used to be invited together with 32 different members of Pulsar’s ProStaff workforce. This group contains handpicked hunters and shooters from all over the world who use thermal gear extensively. Every year, Pulsar selects new members to check and consider merchandise, seize thermal content material, and contribute suggestions that helps form future growth.

For full transparency, I’ve been a part of the ProStaff since round 2019. Whereas I’ve acquired reductions and entry to T&E merchandise, I’ve by no means been paid or earned commissions. My suggestions has come from real-world expertise whereas sharing my hunts and generated content material on Instagram.

Pulsar Manufacturing

Many thermal optics as we speak are produced in China, however Pulsar has made a deliberate option to maintain its manufacturing and meeting operations in Europe. This determination avoids direct assist of the CCP, which is one thing that issues to many hunters and shooters, and likewise helps Pulsar keep nimble within the face of shifting international tariffs.

Obtainable on GunsAmerica Now

The power we toured is positioned in Lithuania, however Pulsar additionally operates one other meeting location in Sweden and a producing base in Latvia. These totally different websites give them flexibility in manufacturing and assist maintain costs secure for customers.

Pulsar Meeting

As soon as elements are machined, molded, or shaped, they’re despatched to Pulsar’s meeting services. Throughout our go to to the Lithuanian website, we walked by rooms the place expert technicians have been hand-assembling merchandise from each class of their lineup. With thermal know-how evolving so shortly, automation for many meeting isn’t sensible. Pulsar is dependent upon skilled employees to construct every unit with precision.

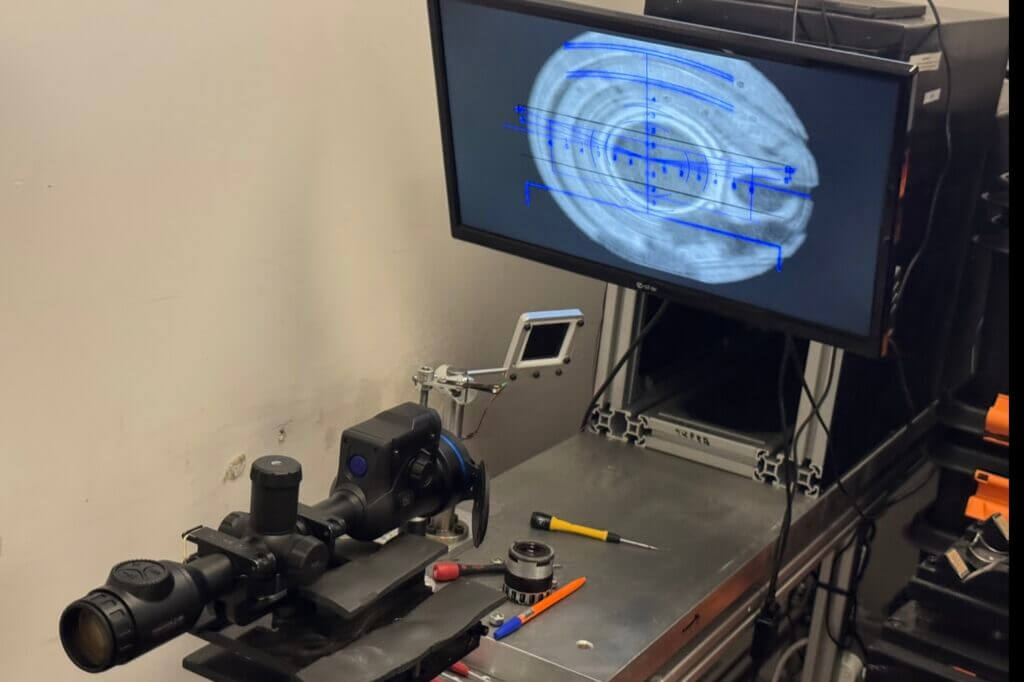

One course of that caught my consideration was their methodology for calibrating laser rangefinders. Every module is first checked for correct alignment of the emitting and receiving channels. After it’s put in right into a testing gadget, the optical axis of the scope is aligned with the laser’s emitting axis to make sure correct ranging efficiency. This stage of element ensures that your ranged distance is true to the ranging reticle constructed into the show.

Testing

Earlier than leaving the manufacturing facility, each thermal product undergoes an intensive inspection. Pulsar performs waterproof testing on one hundred pc of its gadgets. Riflescopes and clip-ons additionally undergo recoil testing rated as much as 6,000 joules. This ensures that even after repeated use with bigger calibers, the optics preserve their efficiency with out a shift in focus or inside harm.

It’s that form of sturdiness testing that offers hunters and professionals confidence within the subject. And with a 5-year guarantee on each thermal unit, Pulsar provides a layer of peace of thoughts for anybody investing of their merchandise.

Palms-On Time

In the course of the journey, our group had the possibility to get hands-on with each scope, scanner, and binocular Pulsar presents. Most of us already personal a number of of their gadgets, however this gave us a uncommon alternative to check all of the totally different fashions facet by facet.

To make issues much more fascinating, Pulsar organized a pleasant competitors. We shot freehand at 100 yards utilizing each .17 HMR and .308 rifles, tracked a shifting paper boar goal at 35 yards, and even completed with a skeet shoot—the one half performed with out thermal. It was reminder that lots of Pulsar’s thermal optics are efficient in the course of the day, not simply at night time.

As soon as the solar went down, we examined each product beneath actual subject situations. Tables have been arrange with side-by-side shows of each scope and handheld. This allowed us to guage readability, refresh charge, detection vary, and different options with direct comparisons in a real-world setting. Whereas this helped sharpen our preferences, most of our product information nonetheless comes from prolonged subject time again dwelling.

Group Discussions

All through the week, we spent round 10 hours in structured discussions with Pulsar workers. These weren’t advertising and marketing shows; they have been working classes targeted on what we preferred, what we didn’t, what firmware adjustments have improved usability, and what we’d wish to see within the subsequent technology of merchandise.

Greater than a dozen Pulsar staff participated, together with workers from R&D, product growth, and advertising and marketing. They listened fastidiously, took notes, requested questions, and knew the gear nicely. It was refreshing to see an organization put critical effort into listening to from those that really use their optics within the subject, week in and week out.

Abstract

This journey to Pulsar’s headquarters supplied rather more than a manufacturing facility tour. It gave us a glance right into a model that values high quality, craftsmanship, and real suggestions. From hand-built optics and wanted inside testing to significant time spent with skilled hunters, Pulsar is aiming to construct thermal instruments that replicate the wants of those that depend on them. Whereas I kept away from nerding out over lots of the specifics, it’s good to know there’s an organization targeted on real-world efficiency, sturdiness, and buyer enter each step of the way in which.

*** Purchase and Promote on GunsAmerica! ***